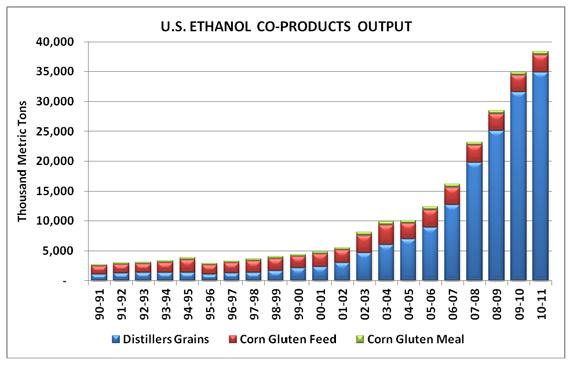

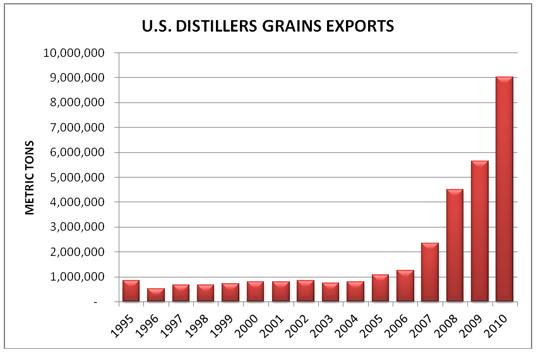

Distiller's Dried Grains with Solubles (DDGS) is a co-product of the distillery industries. Most (~98%) of the DDGS in North America comes from dry-grind plants that produce ethanol for use in oxygenated gasoline. The remaining 1 to 2% of DDGS is produced by the alcohol beverage industry. The nutritional composition of DDGS is different than other co-products such as corn gluten feed and corn gluten meal that are produced by the wet milling sector of the ethanol industry, and is also nutritionally different from brewers grains which are the co-product from beer production facilities. In the U.S. most of the DDGS produced is derived from corn (maize), but small amounts of sorghum (milo) DDGS is also produced. The production of DDGS has increased dramatically since 2000, and the total amount produced in 2011 was approximately 35 million metric tonnes (Figure 1). Exports of DDGS during this period of time also increased dramatically with over 9 million metric tonnes delivered to over 50 countries around the world in 2010 (Figure 2). In North America, approximately 20% of the DDGS produced is fed to swine and poultry with the remaining 80% of distiller’s grains being fed to dairy and beef cattle as wet or dried co-product.

Figure 1.

Source: Renewable Fuels Association (2012).

Figure 2.

Source: USDA-FAS.

Production and Composition of Distiller's By-Products

Distiller's dried grains with solubles are the dried residue remaining after the starch fraction of corn is fermented with selected yeasts and enzymes to produce ethanol and carbon dioxide. After complete fermentation, the alcohol is removed by distillation and the remaining fermentation residues are produced including wet distillers grains, condensed distillers solubles, and modified wet distillers grains, which are fed to ruminants, or the condensed distillers solubles is combined with the wet distillers grains fraction and dried to produce DDGS. Of all of these co-products, DDGS is the predominant form produced and available to the global feed industry.

During the past two years, an increasing number of U.S. dry-grind ethanol plants have begun extracting a portion of corn oil from the thin stillage (precursor to condensed distillers solubles) before producing DDGS. Corn oil extraction systems have been added to existing ethanol plants to increase the energy efficiency of the plant as well as increase the total amount of fuel that is produced per metric tonne of corn processed. The installation of corn oil extraction equipment in an existing ethanol plant facilitates the production of a biodiesel feedstock without affecting ethanol production volumes. Different corn oil extraction technologies are available commercially to the ethanol industry. This process results in a 2 to 3 percentage point reduction in crude fat content of DDGS resulting in reduced-oil DDGS typically containing 7 to 9% crude fat compared to 10 to 12% crude fat in traditional DDGS.

Despite the use of oil extraction by the majority of ethanol plants in the U.S., DDGS continues to be a high quality, high energy, mid-protein, high digestible phosphorus ingredient that is frequently used in significant amounts beef, dairy, poultry, swine, and aquaculture feeds to provide excellent nutritional value often at a reduced cost.